The Role of Cylinder Head Manufacturers in the Diesel Engine Industry

The cylinder head manufacturers play a pivotal role in the overall performance and efficiency of diesel engines. Understanding the intricate details behind the production of cylinder heads can equip businesses and consumers alike with the knowledge needed to make informed purchasing decisions. At client-diesel.com, we pride ourselves on providing high-quality diesel engine parts to our clients, ensuring reliability and performance.

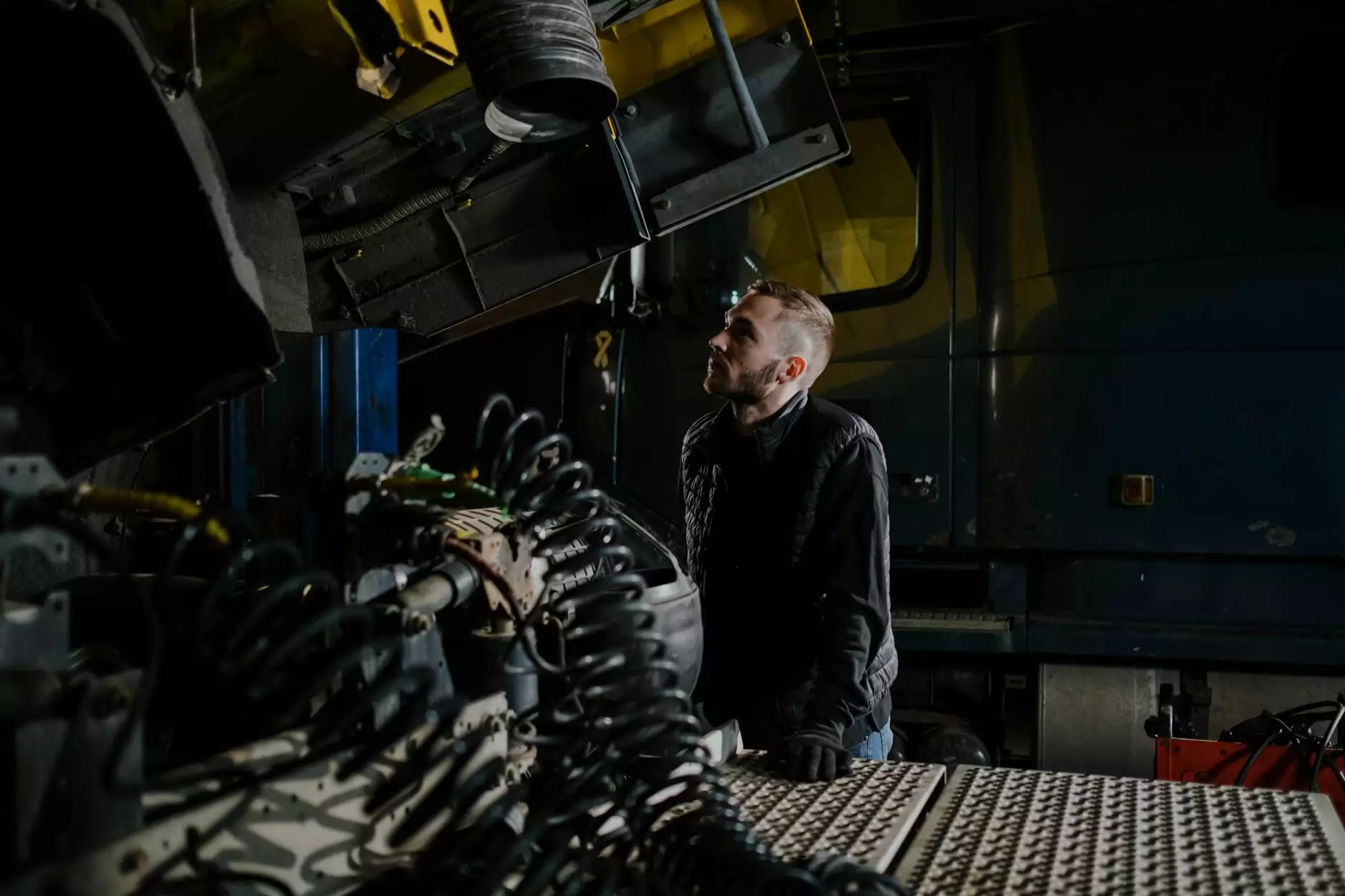

Understanding Cylinder Heads

The cylinder head is a critical component of an engine that houses the valves, spark plugs, and fuel injectors. It plays a significant role in the engine's combustion process, directly impacting efficiency, power, and emissions. Given its importance, choosing the right cylinder head manufacturers is essential for any business involved in diesel engine maintenance or manufacturing.

Types of Cylinder Heads

Cylinder heads can be classified into various types, each serving a unique purpose:

- Cast Iron Cylinder Heads: Known for their durability and heat-resistant properties, cast iron heads are often used in heavy-duty diesel engines.

- Aluminum Cylinder Heads: Lightweight and good for heat dissipation, aluminum heads are typically found in high-performance engines.

- Composite Cylinder Heads: Made from materials that combine metals and other elements, composite heads are increasingly popular for their strength and weight advantages.

Importance of Quality in Cylinder Head Manufacturing

The quality of a cylinder head directly impacts the overall performance and longevity of a diesel engine. Poorly manufactured cylinder heads can lead to significant issues such as:

- Cracking: High thermal stress can cause cracks, resulting in loss of compression and power.

- Warping: Uneven surfaces can lead to poor sealing, causing leaks in the combustion chamber.

- Corrosion: Inferior materials can fail prematurely, leading to additional repair costs.

Key Factors in Evaluating Cylinder Head Manufacturers

When selecting a manufacturer for cylinder heads, consider the following factors:

- Manufacturing Process: Look for manufacturers who use advanced techniques like precision machining, CNC technology, and rigorous quality control.

- Material Quality: Ensure the manufacturer uses high-grade materials that meet industry standards for durability and performance.

- Reputation and Experience: Choose manufacturers with a solid reputation and extensive experience in the industry.

- Customer Feedback: Research online reviews and testimonials to gauge customer satisfaction.

How Client-Diesel.com Stands Out

At client-diesel.com, we are committed to excellence in providing high-quality diesel engine parts, including our carefully manufactured cylinder heads. Here’s how we differentiate ourselves:

Comprehensive Product Range

We offer a wide variety of diesel engine parts, ensuring that our customers have access to everything they need under one roof. From cylinder heads to fuel injectors, our selection is designed to meet the diverse needs of our clientele.

Exceptional Quality Assurance

We implement stringent quality control measures throughout our manufacturing process. Every cylinder head undergoes thorough testing to meet or exceed OEM specifications, guaranteeing performance, reliability, and longevity.

Expert Consultation

Our team of experienced professionals is always ready to assist customers with technical advice, product selection, and any queries regarding our products. We understand the complexities of diesel engines and are here to help.

Innovations in Cylinder Head Technology

The industry is continually evolving, with advances in technology leading to improved manufacturing practices. Some of the latest innovations among cylinder head manufacturers include:

3D Printing Technology

3D printing is revolutionizing the way cylinder heads are manufactured, allowing for intricate designs that were previously impossible to achieve. This technology enables quicker prototyping and customized solutions tailored to specific engine requirements.

Advanced Material Science

The development of new materials, such as lightweight alloys and ceramics, allows for better heat resistance and strength, leading to improved engine efficiency and performance.

Improved Casting Techniques

Modern casting techniques, such as lost foam casting and investment casting, provide superior surface finishes and tighter tolerances, reducing the risk of defects in the final product.

The Future of Cylinder Head Manufacturing

As the demand for diesel engines continues, particularly in heavy-duty applications, the importance of reputable cylinder head manufacturers cannot be overstated. The future will likely see even greater focus on sustainability, with manufacturers innovating to produce eco-friendly products without sacrificing performance.

Sustainability in Manufacturing

Many manufacturers are beginning to adopt greener practices by sourcing recycled materials, minimizing waste, and reducing energy consumption during production. This trend not only benefits the environment but also appeals to a growing demographic of eco-conscious consumers.

Digital Transformation

The integration of digital technologies such as IoT and AI into manufacturing processes will enhance operational efficiency and product quality. Predictive maintenance, for instance, will enable manufacturers to anticipate issues before they arise, ensuring optimal production conditions.

Conclusion

In conclusion, the selection of the right cylinder head manufacturers is critical for anyone involved in the diesel engine industry. Quality, performance, and reliability should always be priorities when procuring engine parts. With trusted suppliers like client-diesel.com, you can rest assured that you are getting only the best when it comes to diesel engine components.

For more information about our products and services, visit client-diesel.com and discover how we can help enhance your diesel engine performance today.